ELEMENTS that are not published (RESERVE)

ELEMENTS that are not published (RESERVE)

RESERVATION FOR THE SCHONEWEG ANNUAL CALENDAR 2023

RESERVATION FOR THE SCHONEWEG ANNUAL CALENDAR 2023 *

SHORT DESCRIPTION

wound filter candles made of polymers (polyester and polypropylene) and cotton

Wound filter candles consist of a support core and a filter medium wound around the support core. The nominal filter fineness of these depth filter elements (the contaminated liquid is fed in from the outside, then passed through the winding material, which holds the particles to be separated, and finally discharged cleaned through the inner support core (precoat filter)) is determined by the thickness of the filter layer, the type of winding and the winding process. Wound filter candles are available in versions with a filter material made of polyester, polypropylene or natural and mineral fibers. The support cores are made of polymers or metal. Wound filter candles are used in candle filter housings (single or multiple to increase the filter surface). The fineness / permeability is usually between 0.5 μm and 200 μm. In addition to the material, important options in the specific specification are the length, diameter, temperature resistance and max. differential pressure. Further options are available on request.

activated carbon filter candles

(Prefilter made of polypropylene - meltblown, wound or fleece)

Activated carbon filter candles are used in particular where chlorine, organic compounds (oils, fats, pesticides, colorants), as well as flavors and odors have to be filtered out of water or aqueous solutions. Typical areas of use are therefore water treatment or applications in the areas of beverages, food and electroplating. The way these deep filter elements work is that the contaminated liquid is fed in from the outside and then passed through the activated carbon elements, in which the particles to be separated are held and finally discharged cleaned through the inner support core (precoat filter). A component of an activated carbon filter candle is a "pre-filter", namely a fleece, polypropylene or polypropylene meltblown (thermally bonded polypropylene microfibers). The components of the activated carbon filter candles are suitable for contact with food (FDA). The fineness/permeability is usually between 1 μm and 10 μm. In addition to the material, important options in the specific specification are the length, diameter, temperature resistance and the maximum differential pressure. Further options are available on request.

MELTBLOWN filter candles

made of polyamide or polypropylene (with / without support core)

Meltblown filter candles consist of thermally bonded polypropylene or polyamide microfibers (without any additional binding agents) and are available with or without a support core. The way these depth filter elements work is that the contaminated liquid is fed in from the outside and then passed through the solid filter structure made of polypropylene or polyamide, in which the particles to be separated are held (precoat filter). Typical areas of application are the filtration of drinking water, galvanic baths, chemicals, cooling lubricants and emulsions. Different lengths and different connection types are possible for use in filter candle housings. The components of the meltblown filter candles are suitable for contact with food (FDA). The fineness / permeability is usually between 0.5 μm and 150 μm. In addition to the material, important options in the specific specification are the length, diameter, temperature resistance and max. differential pressure. Further options are available on request.

membrane filter candles

(100% polypropylene according to FDA requirements)

Membrane filter candles are depth filter elements made of pleated polypropylene microfibers. A carrier fleece on both sides supports the filter element, the elements of which (external protection, support core, end caps and adapter) are made of pure polypropylene. The way these depth filter elements work is that the contaminated liquid is fed in from the outside and then passed through the polypropylene filter structure, in which the particles to be separated are held (precoat filter). The large filter surfaces created by the pleating have a high dirt absorption capacity. Due to their high chemical resistance, membrane filter candles are suitable for use in almost all processes, including contact with food (FDA). The fineness / permeability is usually between 0.2 μm and 100 μm. In addition to the material, important options in the specific specification are the length, diameter, temperature resistance and maximum differential pressure. Further options are available on request.

filter candles

made of stainless steel

Filter candles made of stainless steel are mechanically effective surface filters that are used where the requirements for resistance to heat and chemicals dictate this. The fineness of the mesh defines the maximum size of the particles that are separated. Alternatively, DOE versions ("Double Open End": open on both sides) or SOE versions ("Single Open End": open on one side) with various connections (also for adapters) are available. The alternatively smooth filter surface can be enlarged by pleating. Filter candles made of metal mesh are oil-free, thermally degreased and free of adhesives. Support cores and, if necessary, outflow fabric are used to protect against differential pressure. The fineness/permeability is usually between 1 μm and 1,000 μm. The key options in the specific specification are the length, diameter, temperature resistance and the maximum differential pressure. Other options, e.g. connection types or design (smooth, pleated), are available on request.

QUOTE REQUEST & CHECKLIST FOR FILTER CANDLES

You already know what you need - record and send us your requirements (specifications)

Tell us the requirements of your application or project - either via our checklist and / or by sending your documents - so that we have information about your needs. We will evaluate this information and get back to you.

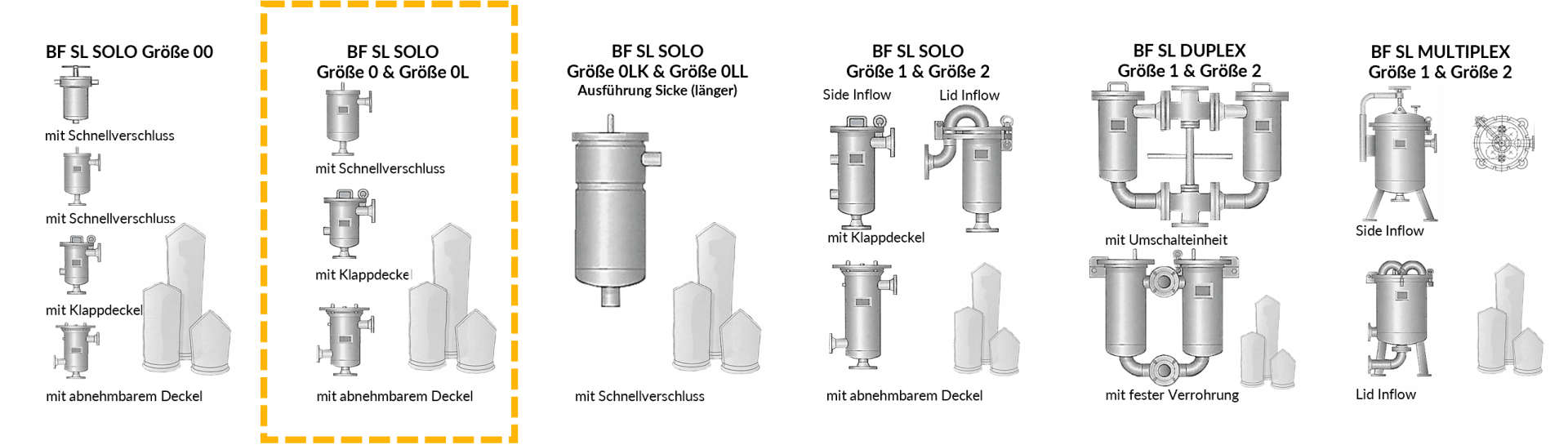

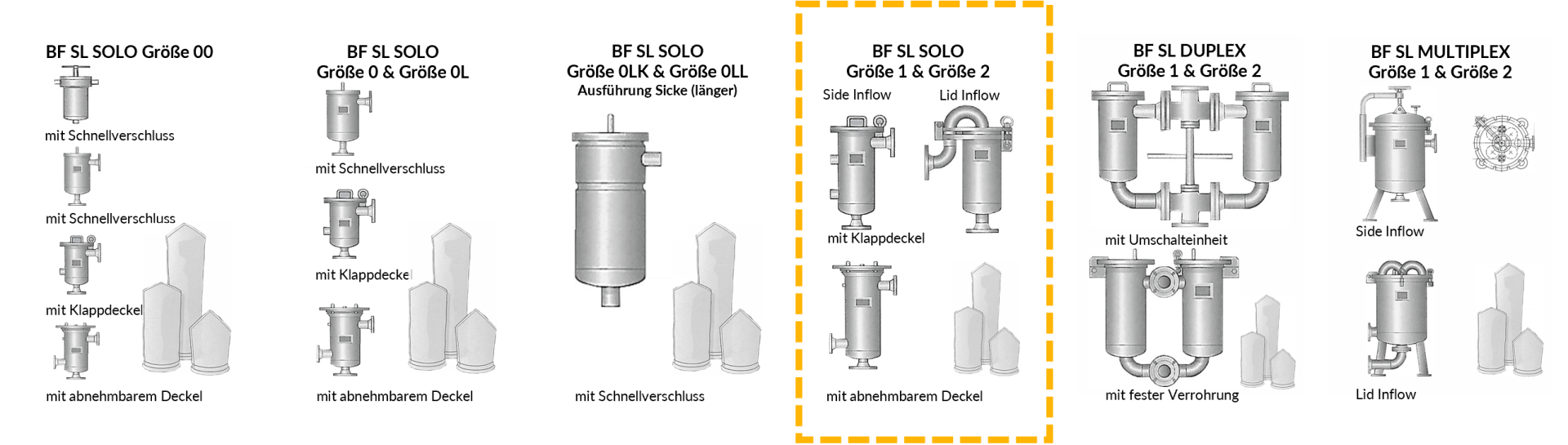

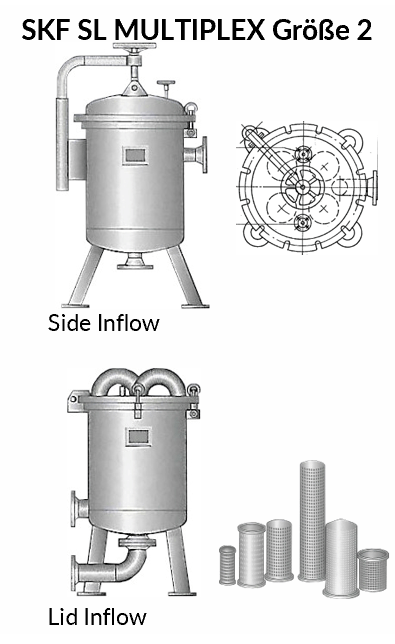

BASKET FILTER SYSTEMS of LIGHT-LINE

SPECIFICATIONS & VARIANTS

suitable needle felt filter bags or monofilament filter bags

- Polyamide [NMO], polypropylene, polyester,

- in standard or individual sizes,

- all subtleties / permeabilities,

- with matching rings/collars,

- in many shapes and designs as well as

- with further options (e.g. FDA / EC conformity)

is here: